Photo 1 Click on thumbnails to enlarge image. Use back button to return

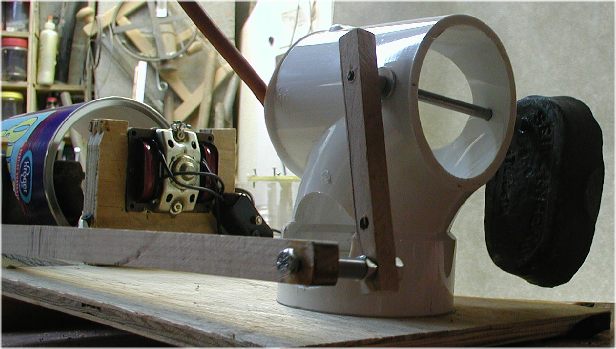

This design was the arrangement that inspired

the need to design a simple to build version. It surely was not simple.

This design was the arrangement that inspired

the need to design a simple to build version. It surely was not simple.

Photo 3

This version under construction is shown with two bevel

gears rather than the "Crooked" crankshaft and PVC pipe. Gears

might be a better way for some builders. A ratio of two to one is good

and with careful alignment of the gears should result in low friction.

This version under construction is shown with two bevel

gears rather than the "Crooked" crankshaft and PVC pipe. Gears

might be a better way for some builders. A ratio of two to one is good

and with careful alignment of the gears should result in low friction.

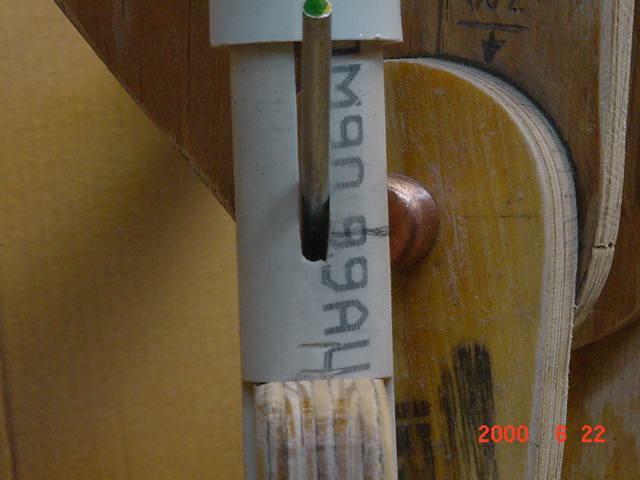

Photo 2

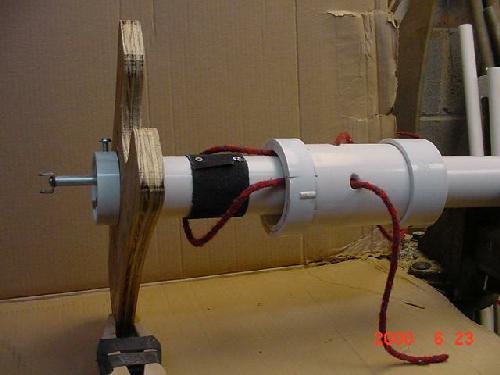

This detail is the heart of this design. The action of the bent rod working in

the slot of the short section of PVC pipe turns the

oar blade to cause it's carrier to rotate due to the flow past the hull

and generate the force needed to steer the boat. The position of the three

rotation axes also provides for the necessary feed back for smooth control.

This detail is the heart of this design. The action of the bent rod working in

the slot of the short section of PVC pipe turns the

oar blade to cause it's carrier to rotate due to the flow past the hull

and generate the force needed to steer the boat. The position of the three

rotation axes also provides for the necessary feed back for smooth control.

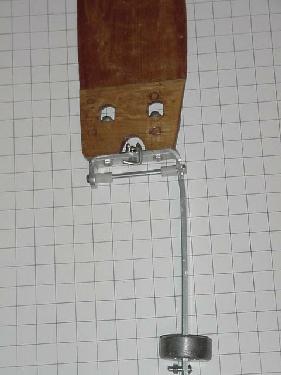

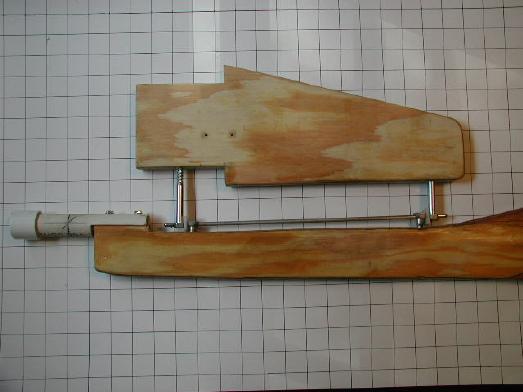

Photo 4

This shows the crankshaft turned to the full extent of the

travel allowed by the wind vane's 45 degree rotation.

This shows the crankshaft turned to the full extent of the

travel allowed by the wind vane's 45 degree rotation.

Photo 70

A stainless steel tube rather than a PVC one.

This is not much more difficult to fabricate. Take care to get

good alignment to avoid binding on the shaft.

A stainless steel tube rather than a PVC one.

This is not much more difficult to fabricate. Take care to get

good alignment to avoid binding on the shaft.

For an even simpler version--Use hardwood blocks well

greased

and aligned with the bent shaft as shown. The "Z" bar in this

photo is also easier to bend than the one in Photo 5 below.

The loop part allows the start of the angled leg to be

accurately bent. The Oar axis and the carrier pivot axis must

intersect at the red spot and both must intersect at the same

point in the vertical plane. There should be no binding in either

direction and minimum free play from the vane to the oar.

For an even simpler version--Use hardwood blocks well

greased

and aligned with the bent shaft as shown. The "Z" bar in this

photo is also easier to bend than the one in Photo 5 below.

The loop part allows the start of the angled leg to be

accurately bent. The Oar axis and the carrier pivot axis must

intersect at the red spot and both must intersect at the same

point in the vertical plane. There should be no binding in either

direction and minimum free play from the vane to the oar.

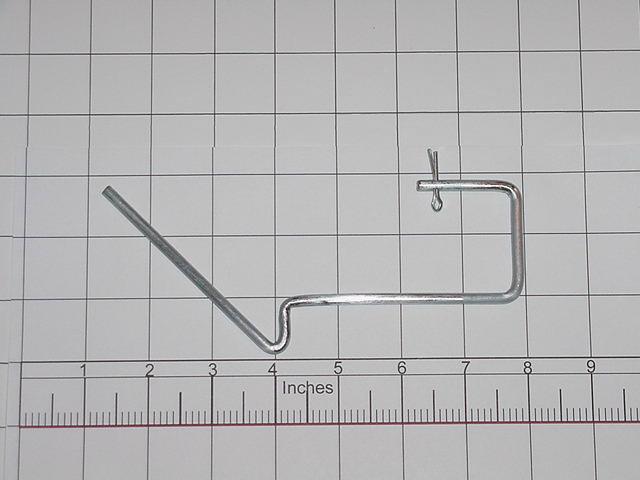

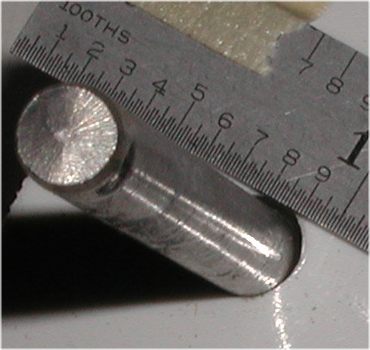

Photo 5

A

dummy part made as a photo "prop" to illustrate the

bend and angles of the crankshaft part. The input and output are

90 degrees apart on the real version and the straight shaft section

is also longer than shown here. See the "More Photos" page for

a series of how to bend pictures.

A

dummy part made as a photo "prop" to illustrate the

bend and angles of the crankshaft part. The input and output are

90 degrees apart on the real version and the straight shaft section

is also longer than shown here. See the "More Photos" page for

a series of how to bend pictures.

Photo 6

The

vane is made of any light, stiff wood such as fir plywood.

The cheek pieces are

glued on and provide a mounting base for

bolting it to the carrier bar.

Several builders have reported the need to increase the area of

this design by about 50 %.

The

vane is made of any light, stiff wood such as fir plywood.

The cheek pieces are

glued on and provide a mounting base for

bolting it to the carrier bar.

Several builders have reported the need to increase the area of

this design by about 50 %.

Photo 7

The

carrier and counter weight bar is made from either

an aluminum bar or a thinner steel bar of the same width. The counter weight will be about two pounds of lead that is adjustable up and down

the bar for fine

tuning the system's response in light air conditions.

The

carrier and counter weight bar is made from either

an aluminum bar or a thinner steel bar of the same width. The counter weight will be about two pounds of lead that is adjustable up and down

the bar for fine

tuning the system's response in light air conditions.

Photo 8

This

"exploded" view shows the course setting line and the mast support.

The platform here is shaped to fit the boomkin

on the boat in photo number 1. The black ban is a section of abrasive

cloth to provide friction for the course sitting line.

This

"exploded" view shows the course setting line and the mast support.

The platform here is shaped to fit the boomkin

on the boat in photo number 1. The black ban is a section of abrasive

cloth to provide friction for the course sitting line.

Photo 9

Vane

support detail showing the vane crank fitting

and upper end of the push rod.

Vane

support detail showing the vane crank fitting

and upper end of the push rod.

Photo 10

The

base of the mast support with the course setting

line showing the mounting screw holes.

The

base of the mast support with the course setting

line showing the mounting screw holes.

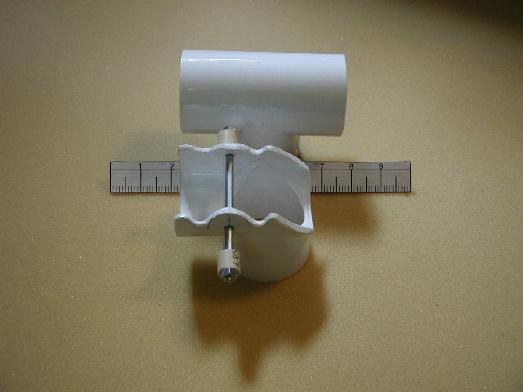

Photo 15

Cut from a schedule 40 PVC pipe Tee fitting

Cut from a schedule 40 PVC pipe Tee fitting

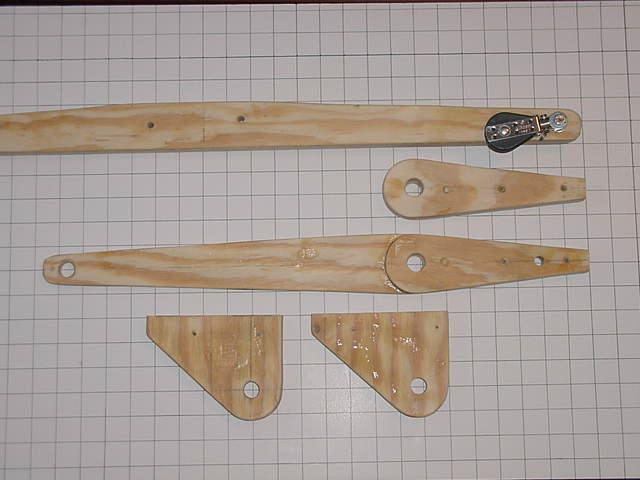

Photos 16 17 18 21 23

Photos 11

12

13

14

23

Plywood parts for platform and oar carrier shown over a one inch grid

board

Plywood parts for platform and oar carrier shown over a one inch grid

board

Photo 20

An all wood vane and carrier.

An all wood vane and carrier.

Photo 27

Detail of lower end of push rod. Note this fitting is

free to rotate around the screw to allow the vane to be set

to the desired course.

Detail of lower end of push rod. Note this fitting is

free to rotate around the screw to allow the vane to be set

to the desired course.

Photo 28

The oar shown here has no provision for kick up

or release in the event it catches on something. For use in

serious cruising a means of relieving the load should be used.

A simple hinged blade held in a detent will work well.

See Photo 25 for one way to do this.

The oar shown here has no provision for kick up

or release in the event it catches on something. For use in

serious cruising a means of relieving the load should be used.

A simple hinged blade held in a detent will work well.

See Photo 25 for one way to do this.

Photo 29

Detail of the Lag bolt hinges and rod.

Detail of the Lag bolt hinges and rod.

Photo 25

Spring loaded kick up blade mounting device.

Spring loaded kick up blade mounting device.

Photo 65

Life testing of stainless crank swinging 45 degrees

either side of vertical turning in a PVC pipe fitting loaded with

a five pound lead weight. Photo made after about 35 minutes

of run time. Test cycling 14 cycles per minute

Life testing of stainless crank swinging 45 degrees

either side of vertical turning in a PVC pipe fitting loaded with

a five pound lead weight. Photo made after about 35 minutes

of run time. Test cycling 14 cycles per minute

Photo 66

Wear after 500,000 cycles. I scale this egging to be

about 0.04 inches and insignificant for the loading and number of

cycles run with no lubrication.

Wear after 500,000 cycles. I scale this egging to be

about 0.04 inches and insignificant for the loading and number of

cycles run with no lubrication.